西安鍛銅雕塑淺析銅材料以及加工工藝

來源:內射XXX韓國在線觀看:boshidiaosu.com 發布時間:2019年01月11日

金屬是內射XXX韓國在線觀看:西安鍛銅雕塑中最常見的材料之一,在鍛銅雕塑藝術發展的歷史長河中,用不同種類的金屬制造的雕塑作品非常多而且有非常重要的歷史地位和價值。不論是純粹的雕塑藝術還是日常生活所用的器皿都有金屬雕塑的優秀范例。金屬是天然的材料,它具有永恒性和高貴性,從而具有廣泛的實用價值和審美價值。金屬材料硬度高、韌性好、光澤亮,是雕塑的主要材料之一。金屬材料經過高溫可以溶化成液體,然后將其澆注入相應的模具里,待其冷卻之后即可成型為雕塑。古代人們所使用的工具、生活用品、打仗的武器都是如此制成,我國在很早以前的夏商周到春秋戰國時期的青銅器鑄造就已經達到了一個頂峰。而銅材料是制作雕塑的主要金屬材料。

一、銅的物(wu)理化學性質(zhi)及其分類

銅(tong)(tong)(tong)(tong)是(shi)(shi)人類發(fa)現最早而且又(you)(you)是(shi)(shi)常被應用(yong)得(de)得(de)心(xin)應手(shou)的(de)(de)(de)(de)材(cai)(cai)(cai)料(liao)。銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)化學符號是(shi)(shi)Cu、原子序數是(shi)(shi)29、原子量(liang)是(shi)(shi)63.546,色(se)澤呈玫(mei)瑰紅(hong)色(se),比重(zhong)是(shi)(shi)8.94,它(ta)的(de)(de)(de)(de)熔(rong)點是(shi)(shi)1083℃,沸點:2582℃,抗(kang)拉強度:220~420MPa。銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)質地軟(ruan)而韌(ren),其(qi)延展(zhan)性(xing)(xing)(xing)(xing)能好(hao)(hao)(hao),易塑性(xing)(xing)(xing)(xing)加(jia)工(gong)(gong),導電(dian)性(xing)(xing)(xing)(xing)及(ji)(ji)導熱性(xing)(xing)(xing)(xing)優良(liang),良(liang)好(hao)(hao)(hao)的(de)(de)(de)(de)拋旋(xuan)光(guang)性(xing)(xing)(xing)(xing),易氧化,尤其(qi)是(shi)(shi)加(jia)熱更(geng)易氧化,不能做(zuo)防護性(xing)(xing)(xing)(xing)鍍(du)層,會(hui)(hui)和空(kong)(kong)氣(qi)中(zhong)的(de)(de)(de)(de)硫(liu)作用(yong)生成(cheng)褐(he)色(se)硫(liu)化銅(tong)(tong)(tong)(tong),會(hui)(hui)和空(kong)(kong)氣(qi)中(zhong)二氧化碳(tan)作用(yong)形(xing)(xing)(xing)成(cheng)銅(tong)(tong)(tong)(tong)錄,會(hui)(hui)和空(kong)(kong)氣(qi)中(zhong)氯形(xing)(xing)(xing)成(cheng)氯化銅(tong)(tong)(tong)(tong)粉末。銅(tong)(tong)(tong)(tong)鍍(du)層具(ju)有(you)良(liang)好(hao)(hao)(hao)均勻性(xing)(xing)(xing)(xing)、致密性(xing)(xing)(xing)(xing)、附著性(xing)(xing)(xing)(xing)及(ji)(ji)拋旋(xuan)光(guang)性(xing)(xing)(xing)(xing)等,所以(yi)可(ke)(ke)做(zuo)其(qi)它(ta)電(dian)鍍(du)金(jin)屬(shu)之底鍍(du)鍍(du)層。鍍(du)層可(ke)(ke)做(zuo)為(wei)防止滲碳(tan)氮化銅(tong)(tong)(tong)(tong),唯一(yi)可(ke)(ke)實用(yong)于(yu)鋅鑄(zhu)件電(dian)鍍(du)打底用(yong)。銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)來源充(chong)足(zu),銅(tong)(tong)(tong)(tong)容易電(dian)鍍(du),容易控制,銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)電(dian)鍍(du)量(liang)僅次于(yu)鎳。銅(tong)(tong)(tong)(tong)材(cai)(cai)(cai)可(ke)(ke)分為(wei)紅(hong)銅(tong)(tong)(tong)(tong)(紫銅(tong)(tong)(tong)(tong))、黃(huang)銅(tong)(tong)(tong)(tong)、青銅(tong)(tong)(tong)(tong)。紅(hong)銅(tong)(tong)(tong)(tong)是(shi)(shi)單純的(de)(de)(de)(de)銅(tong)(tong)(tong)(tong)金(jin)屬(shu),性(xing)(xing)(xing)(xing)軟(ruan)而熔(rong)點低,容易加(jia)工(gong)(gong)。所以(yi)鍛(duan)銅(tong)(tong)(tong)(tong)工(gong)(gong)藝(yi)絕大部(bu)分是(shi)(shi)指紅(hong)銅(tong)(tong)(tong)(tong)而言。紅(hong)銅(tong)(tong)(tong)(tong)性(xing)(xing)(xing)(xing)軟(ruan)富延展(zhan)性(xing)(xing)(xing)(xing),又(you)(you)能很好(hao)(hao)(hao)的(de)(de)(de)(de)表(biao)現作者的(de)(de)(de)(de)創作意圖,且色(se)澤渾厚、穩(wen)重(zhong),可(ke)(ke)和各種裝飾材(cai)(cai)(cai)料(liao)、各種環境配合,既可(ke)(ke)制作大型(xing)壁(bi)畫(hua)、雕塑,又(you)(you)可(ke)(ke)做(zuo)靈活(huo)的(de)(de)(de)(de)局(ju)部(bu)點綴裝飾。所以(yi)這種工(gong)(gong)藝(yi)受到(dao)很多藝(yi)術家的(de)(de)(de)(de)偏(pian)愛(ai),成(cheng)為(wei)許(xu)多壁(bi)畫(hua)、雕塑工(gong)(gong)程的(de)(de)(de)(de)首(shou)選(xuan)材(cai)(cai)(cai)料(liao)。黃(huang)銅(tong)(tong)(tong)(tong)是(shi)(shi)在(zai)純銅(tong)(tong)(tong)(tong)中(zhong)加(jia)入金(jin)屬(shu)錫(xi)冶(ye)煉而成(cheng)的(de)(de)(de)(de),其(qi)性(xing)(xing)(xing)(xing)狀(zhuang)較硬(ying)(ying),相對延展(zhan)性(xing)(xing)(xing)(xing)較差,板材(cai)(cai)(cai)易變形(xing)(xing)(xing),所以(yi)一(yi)般(ban)只適于(yu)制作一(yi)些折皺少、大塊面(mian)積的(de)(de)(de)(de)工(gong)(gong)藝(yi)品,如銅(tong)(tong)(tong)(tong)字、銅(tong)(tong)(tong)(tong)牌等。青銅(tong)(tong)(tong)(tong)是(shi)(shi)在(zai)天然(ran)銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)材(cai)(cai)(cai)料(liao)里(li)加(jia)入了50%的(de)(de)(de)(de)錫(xi)等材(cai)(cai)(cai)料(liao)后(hou)熔(rong)化成(cheng)為(wei)青銅(tong)(tong)(tong)(tong),青銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)硬(ying)(ying)度要比原銅(tong)(tong)(tong)(tong)高,但(dan)是(shi)(shi)熔(rong)點卻(que)由原初的(de)(de)(de)(de)1083℃下降到(dao)800~960℃。銅(tong)(tong)(tong)(tong)材(cai)(cai)(cai)料(liao)易加(jia)工(gong)(gong),有(you)一(yi)定準(zhun)確度,耐(nai)久性(xing)(xing)(xing)(xing)好(hao)(hao)(hao),并有(you)一(yi)種華貴、古雅、莊重(zhong)的(de)(de)(de)(de)色(se)彩。

二、內射XXX韓國在線觀看:西安鍛銅浮雕的加工工藝

二、內射XXX韓國在線觀看:西安鍛銅浮雕的加工工藝

銅(tong)經(jing)過不(bu)(bu)(bu)同(tong)(tong)的加(jia)(jia)工(gong)(gong)(gong)技(ji)術(shu)和(he)工(gong)(gong)(gong)藝(yi)(yi)程序,會(hui)產生(sheng)不(bu)(bu)(bu)同(tong)(tong)的視覺美(mei)(mei)(mei)感和(he)觸覺美(mei)(mei)(mei)感。銅(tong)制雕塑的藝(yi)(yi)術(shu)之(zhi)美(mei)(mei)(mei)是(shi)集材(cai)(cai)質之(zhi)美(mei)(mei)(mei)、工(gong)(gong)(gong)藝(yi)(yi)之(zhi)美(mei)(mei)(mei)和(he)藝(yi)(yi)術(shu)之(zhi)美(mei)(mei)(mei)三(san)者(zhe)綜合的結晶。因此,學習和(he)研究銅(tong)制雕塑需要(yao)(yao)從(cong)這(zhe)(zhe)三(san)者(zhe)入手(shou),即使是(shi)藝(yi)(yi)術(shu)欣(xin)賞也是(shi)需要(yao)(yao)這(zhe)(zhe)三(san)方(fang)面(mian)(mian)來進行(xing),如(ru)果(guo)只(zhi)是(shi)從(cong)一個方(fang)面(mian)(mian)就(jiu)很難了(le)解(jie)和(he)把握銅(tong)制雕塑藝(yi)(yi)術(shu)的真諦(di)和(he)豐富(fu)的內(nei)涵(han)。由于不(bu)(bu)(bu)同(tong)(tong)種類(lei)的銅(tong)材(cai)(cai)料和(he)不(bu)(bu)(bu)同(tong)(tong)造型(xing)(xing)、結構的銅(tong)制雕塑對(dui)加(jia)(jia)工(gong)(gong)(gong)成(cheng)型(xing)(xing)工(gong)(gong)(gong)藝(yi)(yi)的要(yao)(yao)求(qiu)也不(bu)(bu)(bu)同(tong)(tong)。所以成(cheng)型(xing)(xing)和(he)制作方(fang)法(fa)主(zhu)(zhu)要(yao)(yao)包括鑄(zhu)造、鍛造、焊接(jie)(jie)、鉚接(jie)(jie)、切割等(deng)五大(da)加(jia)(jia)工(gong)(gong)(gong)成(cheng)型(xing)(xing)工(gong)(gong)(gong)藝(yi)(yi),而且在裝飾工(gong)(gong)(gong)藝(yi)(yi)方(fang)面(mian)(mian)還主(zhu)(zhu)要(yao)(yao)有(you)鑲(xiang)嵌、雕金、鍍金和(he)鍍銀三(san)大(da)類(lei)。

(一)鑄(zhu)造工藝

鑄(zhu)(zhu)造(zao)工藝(yi)(yi)是(shi)銅雕塑(su)(su)的(de)最古老的(de)成(cheng)型(xing)(xing)工藝(yi)(yi)之(zhi)一,它(ta)的(de)加工方法是(shi)首(shou)先(xian)要(yao)(yao)用黏(nian)土或者(zhe)其它(ta)可塑(su)(su)材(cai)料做出原型(xing)(xing),然后(hou)再翻(fan)(fan)成(cheng)鑄(zhu)(zhu)造(zao)模型(xing)(xing),之(zhi)后(hou)進行(xing)澆鑄(zhu)(zhu)。根據鑄(zhu)(zhu)造(zao)模型(xing)(xing)材(cai)料的(de)不(bu)同,主(zhu)要(yao)(yao)分為陶范(fan)鑄(zhu)(zhu)造(zao)、金(jin)屬范(fan)鑄(zhu)(zhu)造(zao)和失蠟鑄(zhu)(zhu)造(zao)(也(ye)稱翻(fan)(fan)沙鑄(zhu)(zhu)造(zao))。

1、陶范鑄造(zao)

它是(shi)我國最古老的(de)鑄(zhu)造(zao)(zao)技(ji)術之一(yi)(yi),我們(men)的(de)祖先(xian)早在商代就(jiu)(jiu)(jiu)熟練地掌握了這種工藝,并用(yong)此(ci)工藝制(zhi)作(zuo)了大量的(de)青(qing)銅藝術珍(zhen)品,成(cheng)(cheng)(cheng)就(jiu)(jiu)(jiu)了享譽世(shi)界的(de)青(qing)銅文化。陶范鑄(zhu)造(zao)(zao)方法首先(xian)是(shi)制(zhi)范,“范”是(shi)指(zhi)用(yong)于鑄(zhu)造(zao)(zao)的(de)模(mo)子,制(zhi)作(zuo)陶范要(yao)精選細黏土(tu)敷在模(mo)型上(shang)(shang),待半干時分(fen)塊(kuai)取下陰干,干透的(de)泥范再經焙燒成(cheng)(cheng)(cheng)為(wei)陶范①。這就(jiu)(jiu)(jiu)形(xing)成(cheng)(cheng)(cheng)了外(wai)(wai)范,外(wai)(wai)范的(de)分(fen)片(pian)多少視造(zao)(zao)型的(de)復雜(za)程度(du)而定。如果要(yao)鑄(zhu)成(cheng)(cheng)(cheng)中空的(de)雕塑(su)或器(qi)物,在做(zuo)好(hao)的(de)陶范外(wai)(wai)范后還要(yao)做(zuo)陶范內(nei)范,外(wai)(wai)范與(yu)內(nei)范的(de)空間(jian)距(ju)離就(jiu)(jiu)(jiu)是(shi)澆(jiao)鑄(zhu)后的(de)造(zao)(zao)型的(de)厚(hou)度(du)。陶范的(de)上(shang)(shang)部要(yao)預先(xian)做(zuo)好(hao)澆(jiao)注口(kou)和(he)出氣孔。最后把內(nei)、外(wai)(wai)范合起來,并敷上(shang)(shang)泥層進行加固(gu)。做(zuo)好(hao)上(shang)(shang)述工作(zuo),即可以(yi)熔銅澆(jiao)鑄(zhu)了。對(dui)于造(zao)(zao)型復雜(za)的(de)雕塑(su),陶范鑄(zhu)造(zao)(zao)往往無法一(yi)(yi)次(ci)成(cheng)(cheng)(cheng)型,因此(ci)需要(yao)采(cai)用(yong)分(fen)鑄(zhu)法。比如全身(shen)人像雕塑(su),我們(men)將其頭與(yu)身(shen)體、四(si)肢分(fen)別(bie)制(zhi)成(cheng)(cheng)(cheng)陶范,先(xian)將四(si)肢鑄(zhu)好(hao)暫不拿出,再與(yu)軀(qu)干的(de)陶范對(dui)接起來,澆(jiao)鑄(zhu)軀(qu)干時四(si)肢便與(yu)軀(qu)干鑄(zhu)成(cheng)(cheng)(cheng)一(yi)(yi)體了。

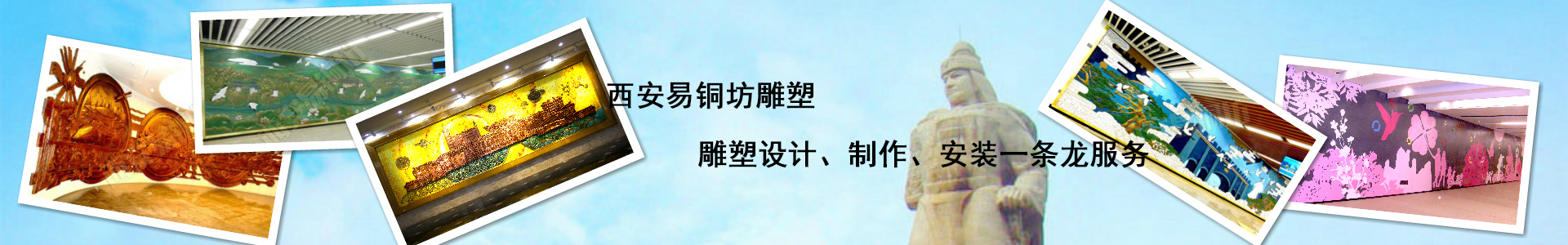

西安易銅坊雕塑工程有限公司(17691083840)公司主要經營內射XXX韓國在線觀看:鍛銅(tong)雕(diao)塑定制,浮雕,不銹鋼雕塑和石雕.擁有多位資深雕塑設計師,從事雕塑和浮雕設計.公司技術力量雄厚,施工隊伍一流。

一、銅的物(wu)理化學性質(zhi)及其分類

銅(tong)(tong)(tong)(tong)是(shi)(shi)人類發(fa)現最早而且又(you)(you)是(shi)(shi)常被應用(yong)得(de)得(de)心(xin)應手(shou)的(de)(de)(de)(de)材(cai)(cai)(cai)料(liao)。銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)化學符號是(shi)(shi)Cu、原子序數是(shi)(shi)29、原子量(liang)是(shi)(shi)63.546,色(se)澤呈玫(mei)瑰紅(hong)色(se),比重(zhong)是(shi)(shi)8.94,它(ta)的(de)(de)(de)(de)熔(rong)點是(shi)(shi)1083℃,沸點:2582℃,抗(kang)拉強度:220~420MPa。銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)質地軟(ruan)而韌(ren),其(qi)延展(zhan)性(xing)(xing)(xing)(xing)能好(hao)(hao)(hao),易塑性(xing)(xing)(xing)(xing)加(jia)工(gong)(gong),導電(dian)性(xing)(xing)(xing)(xing)及(ji)(ji)導熱性(xing)(xing)(xing)(xing)優良(liang),良(liang)好(hao)(hao)(hao)的(de)(de)(de)(de)拋旋(xuan)光(guang)性(xing)(xing)(xing)(xing),易氧化,尤其(qi)是(shi)(shi)加(jia)熱更(geng)易氧化,不能做(zuo)防護性(xing)(xing)(xing)(xing)鍍(du)層,會(hui)(hui)和空(kong)(kong)氣(qi)中(zhong)的(de)(de)(de)(de)硫(liu)作用(yong)生成(cheng)褐(he)色(se)硫(liu)化銅(tong)(tong)(tong)(tong),會(hui)(hui)和空(kong)(kong)氣(qi)中(zhong)二氧化碳(tan)作用(yong)形(xing)(xing)(xing)成(cheng)銅(tong)(tong)(tong)(tong)錄,會(hui)(hui)和空(kong)(kong)氣(qi)中(zhong)氯形(xing)(xing)(xing)成(cheng)氯化銅(tong)(tong)(tong)(tong)粉末。銅(tong)(tong)(tong)(tong)鍍(du)層具(ju)有(you)良(liang)好(hao)(hao)(hao)均勻性(xing)(xing)(xing)(xing)、致密性(xing)(xing)(xing)(xing)、附著性(xing)(xing)(xing)(xing)及(ji)(ji)拋旋(xuan)光(guang)性(xing)(xing)(xing)(xing)等,所以(yi)可(ke)(ke)做(zuo)其(qi)它(ta)電(dian)鍍(du)金(jin)屬(shu)之底鍍(du)鍍(du)層。鍍(du)層可(ke)(ke)做(zuo)為(wei)防止滲碳(tan)氮化銅(tong)(tong)(tong)(tong),唯一(yi)可(ke)(ke)實用(yong)于(yu)鋅鑄(zhu)件電(dian)鍍(du)打底用(yong)。銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)來源充(chong)足(zu),銅(tong)(tong)(tong)(tong)容易電(dian)鍍(du),容易控制,銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)電(dian)鍍(du)量(liang)僅次于(yu)鎳。銅(tong)(tong)(tong)(tong)材(cai)(cai)(cai)可(ke)(ke)分為(wei)紅(hong)銅(tong)(tong)(tong)(tong)(紫銅(tong)(tong)(tong)(tong))、黃(huang)銅(tong)(tong)(tong)(tong)、青銅(tong)(tong)(tong)(tong)。紅(hong)銅(tong)(tong)(tong)(tong)是(shi)(shi)單純的(de)(de)(de)(de)銅(tong)(tong)(tong)(tong)金(jin)屬(shu),性(xing)(xing)(xing)(xing)軟(ruan)而熔(rong)點低,容易加(jia)工(gong)(gong)。所以(yi)鍛(duan)銅(tong)(tong)(tong)(tong)工(gong)(gong)藝(yi)絕大部(bu)分是(shi)(shi)指紅(hong)銅(tong)(tong)(tong)(tong)而言。紅(hong)銅(tong)(tong)(tong)(tong)性(xing)(xing)(xing)(xing)軟(ruan)富延展(zhan)性(xing)(xing)(xing)(xing),又(you)(you)能很好(hao)(hao)(hao)的(de)(de)(de)(de)表(biao)現作者的(de)(de)(de)(de)創作意圖,且色(se)澤渾厚、穩(wen)重(zhong),可(ke)(ke)和各種裝飾材(cai)(cai)(cai)料(liao)、各種環境配合,既可(ke)(ke)制作大型(xing)壁(bi)畫(hua)、雕塑,又(you)(you)可(ke)(ke)做(zuo)靈活(huo)的(de)(de)(de)(de)局(ju)部(bu)點綴裝飾。所以(yi)這種工(gong)(gong)藝(yi)受到(dao)很多藝(yi)術家的(de)(de)(de)(de)偏(pian)愛(ai),成(cheng)為(wei)許(xu)多壁(bi)畫(hua)、雕塑工(gong)(gong)程的(de)(de)(de)(de)首(shou)選(xuan)材(cai)(cai)(cai)料(liao)。黃(huang)銅(tong)(tong)(tong)(tong)是(shi)(shi)在(zai)純銅(tong)(tong)(tong)(tong)中(zhong)加(jia)入金(jin)屬(shu)錫(xi)冶(ye)煉而成(cheng)的(de)(de)(de)(de),其(qi)性(xing)(xing)(xing)(xing)狀(zhuang)較硬(ying)(ying),相對延展(zhan)性(xing)(xing)(xing)(xing)較差,板材(cai)(cai)(cai)易變形(xing)(xing)(xing),所以(yi)一(yi)般(ban)只適于(yu)制作一(yi)些折皺少、大塊面(mian)積的(de)(de)(de)(de)工(gong)(gong)藝(yi)品,如銅(tong)(tong)(tong)(tong)字、銅(tong)(tong)(tong)(tong)牌等。青銅(tong)(tong)(tong)(tong)是(shi)(shi)在(zai)天然(ran)銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)材(cai)(cai)(cai)料(liao)里(li)加(jia)入了50%的(de)(de)(de)(de)錫(xi)等材(cai)(cai)(cai)料(liao)后(hou)熔(rong)化成(cheng)為(wei)青銅(tong)(tong)(tong)(tong),青銅(tong)(tong)(tong)(tong)的(de)(de)(de)(de)硬(ying)(ying)度要比原銅(tong)(tong)(tong)(tong)高,但(dan)是(shi)(shi)熔(rong)點卻(que)由原初的(de)(de)(de)(de)1083℃下降到(dao)800~960℃。銅(tong)(tong)(tong)(tong)材(cai)(cai)(cai)料(liao)易加(jia)工(gong)(gong),有(you)一(yi)定準(zhun)確度,耐(nai)久性(xing)(xing)(xing)(xing)好(hao)(hao)(hao),并有(you)一(yi)種華貴、古雅、莊重(zhong)的(de)(de)(de)(de)色(se)彩。

銅(tong)經(jing)過不(bu)(bu)(bu)同(tong)(tong)的加(jia)(jia)工(gong)(gong)(gong)技(ji)術(shu)和(he)工(gong)(gong)(gong)藝(yi)(yi)程序,會(hui)產生(sheng)不(bu)(bu)(bu)同(tong)(tong)的視覺美(mei)(mei)(mei)感和(he)觸覺美(mei)(mei)(mei)感。銅(tong)制雕塑的藝(yi)(yi)術(shu)之(zhi)美(mei)(mei)(mei)是(shi)集材(cai)(cai)質之(zhi)美(mei)(mei)(mei)、工(gong)(gong)(gong)藝(yi)(yi)之(zhi)美(mei)(mei)(mei)和(he)藝(yi)(yi)術(shu)之(zhi)美(mei)(mei)(mei)三(san)者(zhe)綜合的結晶。因此,學習和(he)研究銅(tong)制雕塑需要(yao)(yao)從(cong)這(zhe)(zhe)三(san)者(zhe)入手(shou),即使是(shi)藝(yi)(yi)術(shu)欣(xin)賞也是(shi)需要(yao)(yao)這(zhe)(zhe)三(san)方(fang)面(mian)(mian)來進行(xing),如(ru)果(guo)只(zhi)是(shi)從(cong)一個方(fang)面(mian)(mian)就(jiu)很難了(le)解(jie)和(he)把握銅(tong)制雕塑藝(yi)(yi)術(shu)的真諦(di)和(he)豐富(fu)的內(nei)涵(han)。由于不(bu)(bu)(bu)同(tong)(tong)種類(lei)的銅(tong)材(cai)(cai)料和(he)不(bu)(bu)(bu)同(tong)(tong)造型(xing)(xing)、結構的銅(tong)制雕塑對(dui)加(jia)(jia)工(gong)(gong)(gong)成(cheng)型(xing)(xing)工(gong)(gong)(gong)藝(yi)(yi)的要(yao)(yao)求(qiu)也不(bu)(bu)(bu)同(tong)(tong)。所以成(cheng)型(xing)(xing)和(he)制作方(fang)法(fa)主(zhu)(zhu)要(yao)(yao)包括鑄(zhu)造、鍛造、焊接(jie)(jie)、鉚接(jie)(jie)、切割等(deng)五大(da)加(jia)(jia)工(gong)(gong)(gong)成(cheng)型(xing)(xing)工(gong)(gong)(gong)藝(yi)(yi),而且在裝飾工(gong)(gong)(gong)藝(yi)(yi)方(fang)面(mian)(mian)還主(zhu)(zhu)要(yao)(yao)有(you)鑲(xiang)嵌、雕金、鍍金和(he)鍍銀三(san)大(da)類(lei)。

(一)鑄(zhu)造工藝

鑄(zhu)(zhu)造(zao)工藝(yi)(yi)是(shi)銅雕塑(su)(su)的(de)最古老的(de)成(cheng)型(xing)(xing)工藝(yi)(yi)之(zhi)一,它(ta)的(de)加工方法是(shi)首(shou)先(xian)要(yao)(yao)用黏(nian)土或者(zhe)其它(ta)可塑(su)(su)材(cai)料做出原型(xing)(xing),然后(hou)再翻(fan)(fan)成(cheng)鑄(zhu)(zhu)造(zao)模型(xing)(xing),之(zhi)后(hou)進行(xing)澆鑄(zhu)(zhu)。根據鑄(zhu)(zhu)造(zao)模型(xing)(xing)材(cai)料的(de)不(bu)同,主(zhu)要(yao)(yao)分為陶范(fan)鑄(zhu)(zhu)造(zao)、金(jin)屬范(fan)鑄(zhu)(zhu)造(zao)和失蠟鑄(zhu)(zhu)造(zao)(也(ye)稱翻(fan)(fan)沙鑄(zhu)(zhu)造(zao))。

1、陶范鑄造(zao)

它是(shi)我國最古老的(de)鑄(zhu)造(zao)(zao)技(ji)術之一(yi)(yi),我們(men)的(de)祖先(xian)早在商代就(jiu)(jiu)(jiu)熟練地掌握了這種工藝,并用(yong)此(ci)工藝制(zhi)作(zuo)了大量的(de)青(qing)銅藝術珍(zhen)品,成(cheng)(cheng)(cheng)就(jiu)(jiu)(jiu)了享譽世(shi)界的(de)青(qing)銅文化。陶范鑄(zhu)造(zao)(zao)方法首先(xian)是(shi)制(zhi)范,“范”是(shi)指(zhi)用(yong)于鑄(zhu)造(zao)(zao)的(de)模(mo)子,制(zhi)作(zuo)陶范要(yao)精選細黏土(tu)敷在模(mo)型上(shang)(shang),待半干時分(fen)塊(kuai)取下陰干,干透的(de)泥范再經焙燒成(cheng)(cheng)(cheng)為(wei)陶范①。這就(jiu)(jiu)(jiu)形(xing)成(cheng)(cheng)(cheng)了外(wai)(wai)范,外(wai)(wai)范的(de)分(fen)片(pian)多少視造(zao)(zao)型的(de)復雜(za)程度(du)而定。如果要(yao)鑄(zhu)成(cheng)(cheng)(cheng)中空的(de)雕塑(su)或器(qi)物,在做(zuo)好(hao)的(de)陶范外(wai)(wai)范后還要(yao)做(zuo)陶范內(nei)范,外(wai)(wai)范與(yu)內(nei)范的(de)空間(jian)距(ju)離就(jiu)(jiu)(jiu)是(shi)澆(jiao)鑄(zhu)后的(de)造(zao)(zao)型的(de)厚(hou)度(du)。陶范的(de)上(shang)(shang)部要(yao)預先(xian)做(zuo)好(hao)澆(jiao)注口(kou)和(he)出氣孔。最后把內(nei)、外(wai)(wai)范合起來,并敷上(shang)(shang)泥層進行加固(gu)。做(zuo)好(hao)上(shang)(shang)述工作(zuo),即可以(yi)熔銅澆(jiao)鑄(zhu)了。對(dui)于造(zao)(zao)型復雜(za)的(de)雕塑(su),陶范鑄(zhu)造(zao)(zao)往往無法一(yi)(yi)次(ci)成(cheng)(cheng)(cheng)型,因此(ci)需要(yao)采(cai)用(yong)分(fen)鑄(zhu)法。比如全身(shen)人像雕塑(su),我們(men)將其頭與(yu)身(shen)體、四(si)肢分(fen)別(bie)制(zhi)成(cheng)(cheng)(cheng)陶范,先(xian)將四(si)肢鑄(zhu)好(hao)暫不拿出,再與(yu)軀(qu)干的(de)陶范對(dui)接起來,澆(jiao)鑄(zhu)軀(qu)干時四(si)肢便與(yu)軀(qu)干鑄(zhu)成(cheng)(cheng)(cheng)一(yi)(yi)體了。

西安易銅坊雕塑工程有限公司(17691083840)公司主要經營內射XXX韓國在線觀看:鍛銅(tong)雕(diao)塑定制,浮雕,不銹鋼雕塑和石雕.擁有多位資深雕塑設計師,從事雕塑和浮雕設計.公司技術力量雄厚,施工隊伍一流。

相關產品

相關文章

- 內射XXX韓國在線觀看:西安鍛銅雕塑,鍛銅佛像制作工藝2018年11月(yue)17日

- 內射XXX韓國在線觀看:西安鍛銅雕塑設計哪家好-易銅坊雕塑2018年11月(yue)29日

- 內射XXX韓國在線觀看:西安鍛銅雕塑廠哪家好-易銅坊雕塑2018年12月04日

- 內射XXX韓國在線觀看:西安鍛銅雕塑在景觀雕塑中的位置2018年12月11日

- 內射XXX韓國在線觀看:西安鍛銅雕塑在城市景觀雕塑中的地位2018年12月26日(ri)